Use an Ultrasonic Record Cleaner to Restore Old Vinyl

|

Let Us Help We can help you

find the perfect storage unit for your needs and budget. |

The 1974 movie "All That Jazz" featured a hit song by Peter Allen "Everything Old is New Again." The title perfectly describes the popularity of old vinyl records and why vinyl record enthusiasts depend on an ultrasonic record cleaner to restore their classic albums. These enthusiasts, as well as merchants selling both new and old vinyl, know that an ultrasonic record cleaner is an important contributor to restoring and maintaining sounds not duplicated on CDs.

Big Money in Old Vinyl Records?

Vinyl record sales are booming due to a renewed interest among younger generations. As a general rule, the rarer the record, more valuable it is — you may have some treasure buried in your garage."

So, whether the records on the Finance 101 list or albums in your garage, cellar or attic qualify, there's no doubt that there's a growing cadre of collectors. Items that come to this poster's mind include the original Dave Brubeck Newport Jazz Festival series, The Brubeck Quartet's Jazz Goes to College, Julie London’s original Julie is her Name album or early Mantovani discs – or even the jukebox 45s of Elvis, Fats Domino, the Everly Brothers or you name it.

Why an Ultrasonic Record Cleaner is Preferred by Audiophiles

Ultrasonic energy is viewed by many as the safest and most effective way to remove dust, dirt, oils and other contaminants from extremely fine record grooves that produce the high-fidelity sound demanded by audiophiles.

The microscopic vacuum bubbles produced in an ultrasonic record cleaner implode with great force to loosen and carry away these contaminants, but the process is so fast there is no damage to the vinyl records being cleaned .

This contrasts sharply with hand washing the records using a sponge or soft brush in a sink with a dishwashing liquid. Chances are results will be entirely unsatisfactory because of remaining dirt and incomplete rinsing. There's also the danger that this process will damage the label.

Moreover, collectors performing ultrasonic record cleaning operations on a regular basis will enjoy better sound, preserve the value of their collections and extend stylus life.

A Collector of Old Vinyl Talks about Ultrasonic Record Cleaning

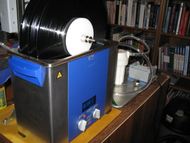

We spoke to Don in Minnesota about his use of a dual-frequency 37/80 kHz Elmasonic P series ultrasonic cleaner and how he uses it to clean his stock of about 5,000 records collected over 40 years.

Don readily admits that with a collection of this size, cleaning is pretty much an ongoing process.

“I also admit I am somewhat of a fanatic when it comes to maintaining the collection,” he says, “but it is amazing to hear the improved sound after thoroughly cleaning vinyl records. The sound of newly purchased records is also improved greatly by cleaning due to removing the mold release chemicals from the disc.”

Tip: How to Use an Ultrasonic Record Cleaner

Don devised a record support system by coupling a 6 RPH motor and shaft assembly to a modified Irwin bar clamp. The assembly is not attached to the ultrasonic cleaner which frees the equipment for other tasks.

Three records are cleaned at a time, separated by spacers at approximately 2 cm apart. This both protects the record labels and allows ultrasonic cavitation to reach the grooves.

The 1.5 gallon capacity ultrasonic cleaning tank is filled with distilled water to which is added 4 ounces of 190 proof grain alcohol and a few drops of Photo Flo.

“I set the ultrasonic frequency to 80 kHz, the thermostat to 40⁰C, and activate the degas function to drive off trapped air while mixing the bath. When the on-board temperature indicator reaches 40⁰ cleaning begins,” he says. “Records are lowered into the bath and rotate for 2 revolutions in 20 minutes – so slow you can hardly see them move. This allows ultrasonic cavitation to remove virtually all contaminants from the grooves.”

At the end of the cycle records are removed from the support system and allowed to dry.

"I found that the Elmasonic cleaner with its 80 kHz frequency and process controls is theoretically a much better choice than other available ultrasonic record cleaners,” Don says.

Going the Extra Step in Ultrasonic Record Cleaning

“There is no doubt that ultrasonic cleaning makes a significant difference in cleanliness. I was amazed at the additional detail on every record – even those I cleaned earlier by different cleaning methods,” Don says.

“For my own satisfaction, however, and confessing to be a perfectionist, I follow up the sonic cleaning by using my Loricraft record cleaning unit. It’s somewhat like an assembly line. Records are removed from the ultrasonic cleaner, dried, then transferred to the Loricraft, and the Elma ultrasonic cleaner is reloaded to clean the next batch.”

Ultrasonic Record Cleaning Kits from iUltrasonic

The case study cited above is but one of several examples where ultrasonic record cleaning is being used to restore old vinyl and maintain new recordings. For the enthusiast or for owners of record stores iUltrasonic offers a selection of record cleaning kits featuring the Elmasonic P series of ultrasonic cleaners.

For more information on how an ultrasonic record cleaner can restore, maintain or offer a service to new or old vinyl enthusiasts, please call or chat with us for details.