Ultrasonic Carb Cleaners: Easy, Fast, Thorough, Eco-Friendly

|

Get Expert Advice Save time. Let us help you

find the perfect cleaning system for your needs and budget. 973-821-3406 | Chat | Email |

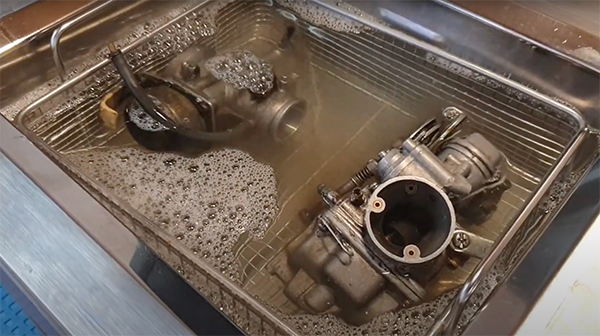

Time was when carburetor cleaning meant time-consuming disassembly, manually spraying or scrubbing parts in solvents, then reassembly. No more.

Ultrasonic carburetor cleaner machine benefits:

- Easy: minimum disassembly required

- Fast: complete cleaning in 25-40 minutes

- Thorough: removes dirt, varnishes and grime unreachable by manual scrubbing

- Eco-Friendly: no harmful gas tank additives, aerosol sprays or solvents

Ultrasonic Carb Cleaner Kits for Backyard Mechanics and Commercial Shops

Ultrasonic carburetor cleaning kits from iUltrasonic contain all a novice or professional needs. They include:

- Your ultrasonic cleaner with timer, heater and user manual

- Stainless steel parts basket and lid

- Easy-to-follow guide: How to Clean Carbs

- Biodegradable cleaning solution concentrate dilutes to 1 to 5% with water

Select Your Ultrasonic Carb Cleaner Kit

Three options are available from iUltrasonic allow you to clean single or multiple carburetors and other engine parts at the same time.

The ultrasonic cleaner for small engine carburetors is the 3/4-gallon SGB 75 Grease Buster ideal for cleaning carburetors typically found on lawnmowers, chainsaws and other small gas-engine powered equipment.

For small engine repair shops, backyard mechanics or motorcycle clubs, consider the 1.6-gallon capacity SGB-160 kit we recommend for these applications. This is also a good choice for preparing winter sports and maintenance equipment.

The 10-gallon SGB 1000 kit is a complete car parts sonic cleaner kit. It is perfect for removing gunk, grease, built-up road dirt and other contaminants from carburetors, fuel pumps, oil pumps, brake assemblies, gears and other components without the mess and bother of manual scrubbing with solvents in wash tanks.

All kits include elma tec clean A4, a biodegradable ultrasonic cleaning solution concentrate diluted to 1 to 5% with water. This means 2.5 liters of elma tec clean A4 makes 15 gallons of cleaning solution!

Three Simple Steps to Ultrasonic Carburetor Cleaning

Whatever the model and size ultrasonic carburetor cleaner kit you use here are steps to take before and during the cleaning cycle:

- Add water to fill the tank half way and add 1 to 5 percent cleaning solution concentrate for a full tank. Continue adding water to the fill line.

- Activate the ultrasound, set the heater to approximately 70°C, and operate the unit for 10-15 minutes. This mixes the solution and degasses cavitation inhibiting entrained air.

- Place parts to be cleaned in the basket, lower them into the solution, cover the unit with the lid to reduce noise and evaporation, and set the timer for 20 minutes. Cleaning time depends on the degree of contamination and/or number of parts being cleaned per cycle.

Safety Note: DO NOT reach into an operating ultrasonic bath. Instead remove the basket if you want to inspect or rearrange the parts. They might be hot.

Maintaining your Carburetor Cleaning Solution

Contaminants removed during ultrasonic carb cleaning float to the top of the solution or fall to the tank bottom.

Periodically skim off contaminants that rise to the surface of the bath and set them aside for later disposal. When the solution becomes discolored, or cleaning time takes longer it is time to replace it.

Empty the tank. Follow local regulations to dispose skimmed off contaminants, spent solution and sludge from the bottom of the tank. Clean the tank following instructions in the user manual.

Fill the tank with fresh cleaning solution, degas it and you are ready for new cleaning cycles.

How Ultrasonic Carb Cleaners Work

Ultrasonic cleaners are used in a wide range of applications to remove virtually any soil or contamination by using the power of cavitation action.

Cavitation is the term used to describe the implosion of billions of minute vacuum bubbles when they contact parts immersed in an ultrasonic cleaning solution. These microscopic bubbles reach tiny cracks, crevices, blind holes and other surfaces impossible to access using brushes and sprays.

When these bubbles contact parts immersed in the solution, they implode to blast loose and carry away contaminants on parts being cleaned.

For more info on the technology see our post how ultrasonic cleaners work.

Have More Questions on Ultrasonic Carb Cleaner Machines?

Contact the experts at iUltrasonic.com for help in selecting the right ultrasonic carb cleaner kit and cleaning solution that meets your requirements.